Caution When Outputting Paper to the Finisher/Stacker

Precautions for the optional Finisher/Stacker

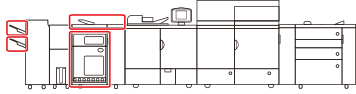

When 2-sided coated paper whose weight is 257 to 300 g/m2 is output into the trays (marked in red in the following illustration), remove the stacked paper before it becomes about 4 cm high. When the same paper type whose weight is 301 to 400 g/m2 is output into the trays, remove the stacked paper before it becomes about 3 cm high. Keeping outputting paper without removing it may cause paper to stick with each other, and the surface may come off. Similar situation may occur with 2-sided coated paper whose weight is 256 g/m2 or below. Remove the stacked paper before it becomes about 14 cm high.

When the paper is delivered to the output tray, the output paper may not be aligned. In this case, set the curl correction and set [Gloss] to [-] side in the Gloss/Fine Black Adjustment mode simultaneously. For more information on the settings, see "Adjusting the Level of Curl Correction" and "Adjusting the Gloss and Fine Black."

If the width of the paper you are using is small, the paper may be stapled (corner/double) with uneven edges. In this case, check the width of the paper.

When the Thin 1 or Thin 2 paper whose length is less than 140 mm is output, the corner of paper may be folded. In this case, perform curl correction to curl the paper upward.

Special types of paper, such as coated paper and embossed paper, may be loaded on the output tray with uneven edges. In this case, perform curl correction to curl the paper upward.

If paper that is curled upward is used with the staple mode, the paper may be stapled with uneven edges. In this case, perform curl correction to curl the paper downward.

When the curled paper is output, the output paper may not be loaded properly on the output tray, and may fall from the tray. In this case, the remedies shown below may be able to prevent the situation.

Changing whether the printed paper is output face up or face down

Changing the paper loading direction

Changing the output destination

Precautions for the Saddle Stitch Mode

If paper that is less than 64 g/m2 is used for the cover page, the paper may be creased when saddle stitched.

If paper that is less than 64 g/m2 is used for the cover page when the Booklet Trimmer-F is used, the paper may be trimmed with uneven edges.

When the saddle stitch mode is set, if a paper jam occurred because of the thickness of the stack, reduce the number of pages in the main document.

If the width of the paper you are using is small, the paper may be saddle stitched with uneven edges. In this case, check the width of the paper.

If the width of the paper you are using is small when the Booklet Trimmer-F is used, parts of the paper may tore off during trimming or the paper may not be trimmed because the trim location cannot be reached. Also, a booklet that is saddle stitched with uneven edges may be trimmed with prints unaligned. In this case, check the width of the paper.

If the optional Booklet Trimmer-F/Booklet Trimmer-F and Two-Knife Booklet Trimmer-A are attached and more than 20 sheets (including 1 cover sheet) are saddle stitched, do not set the Saddle Press setting to off. If the Saddle Press setting is set to off, paper jam may occur.