Correcting Distortion (Parallelogram)

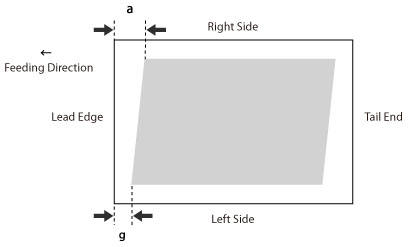

This setting enables you to correct the image shape by equalizing the length from the 'a' and 'g' to the lead edge of the paper when the image is printed like a parallelogram.

|

You can also make the adjustment by using the guide sheet or test page. - When scanning with the feeder Adjusting the Image Position Using the Test Page (When Using a Feeder) - When scanning with the platen glass Adjusting the Image Position Using the Guide Sheet (When Using the Platen Glass) |

1

Press <Change> for <Adjust Image Position>.

2

Press <Do Not Use Scanner> or <Adjust Manually>.

This procedure is not necessary if the optional “Duplex Color Image Reader Unit-P” and “Sensing Unit-B” are not installed.

3

Press <Set Details>  <Corr. Distortion (Parallelogram)>.

<Corr. Distortion (Parallelogram)>.

<Corr. Distortion (Parallelogram)>.

<Corr. Distortion (Parallelogram)>.If you want to enter the values of the test page you measured manually:

|

To adjust the image position on long sheets, print out a long sheet test page. The adjustment can be made more efficiently than with the test page printed out by <Output Test Page> under <Correct Distortion (Parallelogram)>. (The long sheet test page is available from the online manual site.) |

|

If the image position varies greatly, the accuracy of correction may be improved by printing several test pages and using an average of the measured length. |

The test page is printed.

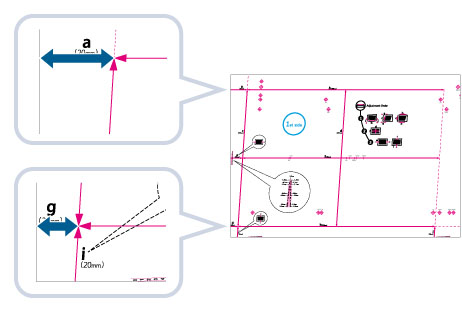

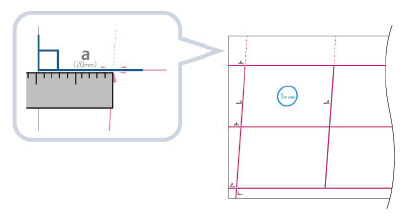

The mark 'g' is printed on the left side lead edge, and the mark 'a' is printed on the right side lead edge of the feeding direction.

Standard size |

|

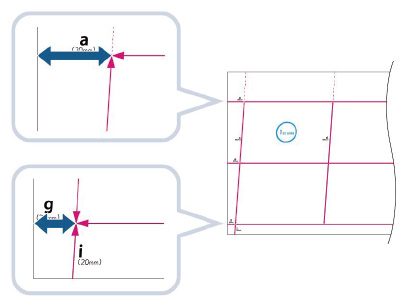

Long sheet |

|

Example: 'g' = 20.5 mm, and 'a' = 21.0 mm

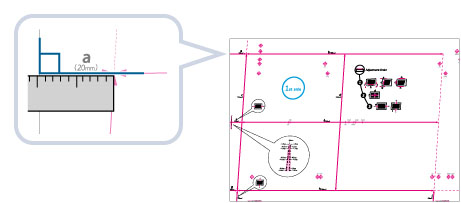

Measure the length of the 'g' and 'a' marks correctly as shown below.

Standard size |

|

Long sheet |

|

Using the following two numerical values and "c = 250.0", a device adjusts the length to correct distortion on the printing area.

<g>: | Enter the measured length of 'g' mark on the test page. |

<a>: | Enter the measured length of 'a' mark on the test page. |

Following the example, enter 20.5 for <g> and 21.0 for <a>.

The difference between 'g' and 'a' (0.5 mm) is corrected.

Print a test page again and check the image position as needed. If you need to make a further adjustment, repeat steps above.

If you correct the position using any printed images:

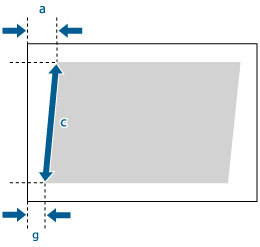

Example: 'c' = 250.0 mm, 'g' = 20.5 mm, and 'a' = 21.0 mm

Using the following three numerical values, a device adjusts the length to correct distortion on the printing area.

<c>: | Enter the measured length from the left side lead edge of the printing area to the right side lead edge of the printing area. |

<g>: | Enter the measured length from the left side lead edge of the printing area to the lead edge of the output paper. |

<a>: | Enter the measured length from the right side lead edge of the printing area to the lead edge of the output paper. |

Following the example, enter 250.0 for <c>, 20.5 for <g>, and 21.0 for <a>.

The difference between 'g' and 'a' (0.5 mm) is corrected.

Print a test page again and check the image position as needed. If you need to make a further adjustment, repeat steps above.

4

Press <OK>  <OK>.

<OK>.

<OK>.

<OK>. |

To restore the accumulated value, press <Restore Initial Settings>. |