Loading Envelopes

Envelopes can be loaded into Paper Drawer 1 and the multi-purpose tray. For information on envelopes that can be loaded, see "Available Paper Stock." For instructions on loading envelopes into the multi-purpose tray, see "Loading Envelopes into the Multi-Purpose Tray."

|

IMPORTANT

|

|

Do not forcefully move the front and left guides of the paper drawer in the wrong direction. Doing so may damage the paper drawer.

Do not print on both sides of an envelope. Doing so may cause paper jams, dirty prints, or make the inside of the machine dirty.

Do not load the following types of envelopes inside the envelope cassette. Doing so may cause paper jams, dirty prints, or make the inside of the machine dirty.

Curled, creased, or folded envelopes

Very thick or thin envelopes

Damp or wet envelopes

Torn envelopes

Irregularly shaped envelopes

Envelopes with clasps or windows

Envelopes that have already been sealed

Envelopes with holes or perforations

Envelopes with specially coated surfaces

Envelopes made of surface treated colored paper

Envelopes that are self-sticking, which use ink, glue, or other substances that can melt, burn, vaporize, or emit smells under the heat of a fixing unit (approximately 392°F). Depending on the materials used for the seal, the glue may melt under the fixing unit's heat, sealing the envelopes.

If you are printing on envelopes, empty the output tray when up to 10 printed envelopes accumulate in the tray.

Envelopes should be stored in a place away from high-temperatures and humidity.

If there is a temperature difference between the location where the envelopes are stored and the location where the envelopes are being printed, leave the envelopes in the printing location at room temperature before you use them.

Correctly match the [Paper Settings] in [Preferences] (Settings/Registration) with the size of the envelopes being loaded. Failure to do so may cause paper jams, dirty prints, or make the inside of the machine dirty.

|

Attaching the Envelope Feeder Attachment

Attach the Envelope Feeder Attachment before loading envelopes to a paper drawer.

|

NOTE

|

|

When using the ISO-C5 envelopes, the Envelope Feeder Attachment does not need to be attached. Proceed to "Preparing the Envelopes."

|

1.

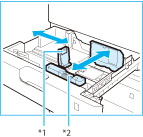

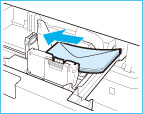

Open the paper drawer, and remove the Envelope Feeder Attachment.

|

(1)Grip the handle, and pull out the paper drawer until it stops. |

(2)Remove the Envelope Feeder Attachment stored inside the paper drawer. |

2.

Attach the Envelope Feeder Attachment by aligning the protruding areas of the Envelope Feeder Attachment with the holes on the paper drawer.

|

NOTE

|

|

Only attach the Envelope Feeder Attachment when loading envelopes. Loading paper other than envelopes with the Envelope Feeder Attachment attached may cause a paper jam.

When not using the Envelope Feeder Attachment, store it in the storage area of the paper drawer.

|

Preparing the Envelopes

This section explains how to prepare the envelopes before loading them into the paper drawer.

|

IMPORTANT

|

|

If envelopes are not neatly aligned before being loaded, a problem with the paper supply or a paper jam may occur. Fix any curls or bends before loading the envelopes.

|

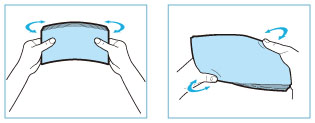

1.

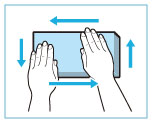

Take five envelopes, loosen them as shown, and then stack them together.

Repeat this step five times for each set of five envelopes.

2.

Place the envelopes on a clean, level surface, and press all the way around the envelopes by hand, in the direction of the arrows, to remove any curls.

Repeat this step five times for each set of five envelopes.

3.

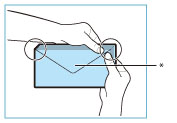

Hold down the four corners of the envelopes firmly, so that they and the sealed or glued portion stay flat.

|

|

|

* Flap

|

4.

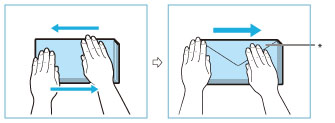

Press the envelope in the direction of the arrows.

|

|

|

* Flap

|

|

IMPORTANT

|

|

Take particular care to spread the envelopes out in the direction that they will be fed.

|

|

IMPORTANT

|

|

If you use envelopes that have glue attached to their flaps, the glue may melt due to the heat and pressure of the fixing unit.

Do not print on the back side of the envelopes (the side with the flap).

If the envelopes become filled with air, flatten them by hand before loading them into the Paper Drawer 1.

|

Loading Envelopes

This section explains how to load envelopes into Paper Drawer 1.

|

IMPORTANT

|

|

Make sure that you change the envelope settings from the Settings/Registration screen before carrying out the following procedure. (See "Paper Settings.") Otherwise, the machine may not recognize the changes you have made.

|

|

NOTE

|

|

For instructions on loading envelopes into the multi-purpose tray, see "Loading Envelopes into the Multi-Purpose Tray".

|

1.

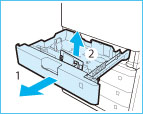

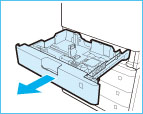

Grip the handle, and pull out the paper drawer until it stops.

2.

Adjust the position of the paper drawer guides.

|

IMPORTANT

|

|

Slide the guides until they click into place. If the left guide and front guide are not aligned correctly, the paper size will not correctly appear on the touch panel display. It is also necessary to adjust the guides correctly to avoid causing a paper jam, dirty prints, or making the inside of the machine dirty.

|

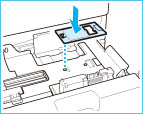

3.

Load the envelopes into the drawer.

|

1. Load 10 envelopes at a time with the side you want to print on facing up. |

2. While loading the envelopes, press down on the right side of the receptacle to lock them into place. |

Align the leading edges of the envelopes, and make sure that they are held in place under the claws.

Make sure that the flaps are positioned as shown in the illustrations below.

|

|

|

|

Monarch, COM10 No.10, DL, ISO-C5

|

Yougatanaga 3

|

Nagagata 3

|

|

IMPORTANT

|

|

Envelopes which have been rolled or curled must be straightened out prior to use.

Make sure that the height of the envelope stack does not exceed the height limit mark (

). ).When loading ISO-C5 envelopes, make sure that the height of the envelope stack does not exceed the height limit mark (

). ).If the flap of an envelope opens and is caught under the Envelope Feeder Attachment, it may cause a paper jam.

Envelopes may not be able to be fed properly if they are loaded at an angle.

|

|

NOTE

|

||||

|

If envelopes are oriented normally when loaded but wrinkle when printed, load envelopes after rotating them 180 degrees, as shown below.

When printing, check that the orientation of the loaded paper matches the orientation shown on the print settings screen of the printer driver. For more information, see the online help. (See "Viewing Help.")

When copying, load originals after rotating them 180 degrees.

|

4.

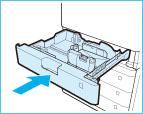

Gently push the paper drawer back into the machine.

|

CAUTION CAUTION |

|

When returning the paper drawer to its original position, be careful not to get your fingers caught, as this may result in personal injury.

|

|

IMPORTANT

|

|

Never place paper or any other items in the empty part of the paper drawer next to the envelopes. Doing so may cause paper jams.

|

|

NOTE

|

|

If output has been stopped due to an insufficient number of envelopes, load more envelopes, and follow the instructions on the touch panel display. Printing resumes.

|

5.

Register the type of envelope on the Settings/Registration screen.

For instructions on registering the envelope type, see "Registering the Paper Size and Type for a Paper Source."