Loading Paper

This section describes how to load paper.

Caution for Paper Curl

If paper jams or poor print quality occur, paper curl is often the cause. The paper stiffness, direction of curl, and amount of curl have a strong influence on how well the paper is transported through the machine. When loading paper, always adjust the curl amount to the appropriate level as described below.

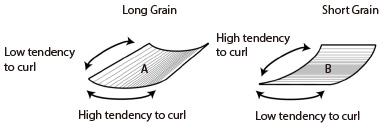

Relationship between Paper Grain and Curl

Paper stiffness depends on the direction of the paper grain. Paper tends to curl in direction parallel to the grain.

When using coated paper whose paper weight is 106 to 128 g/m2 or thin paper whose paper weight is 63 g/m2 or less, we recommend using paper with the grain parallel to the feeding direction of the paper.

Correcting Paper Curl

In order to prevent problems resulted from paper curl, it is necessary to uncurl paper appropriately.

The amount of curl that may cause problems depends on the paper type and thickness. Refer to the instructions below to correct the paper curl so that it is within the acceptable range, and then reload the paper.

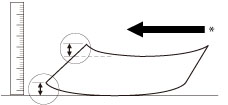

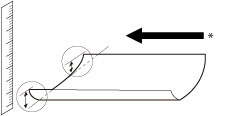

Measuring Paper Curl

Place the paper on a horizontal surface. Place a ruler against the leading edge relative to the paper transport direction, and measure the curl at both ends. If it is a down curl, flip the paper over before measuring the curl.

Measuring a perpendicular curl

* Transport Direction

Measuring a parallel curl

* Transport Direction

IMPORTANT |

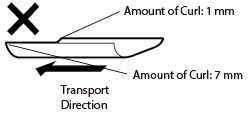

For small and thick paper such as postcards, the difference between the amount of inner and outer curl must be adjusted to less than 5 mm in addition to the conditions given below.  |

Acceptable Curl Range

Acceptable curl range when the curl is perpendicular to the feed direction

If you feed paper from the main unit

If you feed paper from 181 to 220 g/m2 in weight and whose length in the feeding direction is 200 mm or less, we recommend using paper which curls down 5 mm or less. We do not recommend using paper which curls up.

For paper other than above, we recommend using paper which curls up or down 5 mm or less.

If you feed paper from the POD Deck Lite-C, POD Deck Lite XL-A, or Multi-drawer Paper Deck-C

If you feed paper from 221 to 300 g/m2 in weight and whose length in the feeding direction is 200 mm or less, we recommend using paper which curls up 5 mm or less. We do not recommend using paper which curls down.

For paper other than above, we recommend using paper which curls up or down 5 mm or less.

If you feed paper from the Stack Bypass-C

If you feed paper less than 105 g/m2 in weight, we recommend using paper which curls up or down less than 10 mm.

If you feed paper from 106 to 163 g/m2 in weight, we recommend using paper which curls up less than 10 mm or curls down less than 5 mm.

If you feed paper from 164 to 300 g/m2 in weight, we recommend using paper which curls up less than 5 mm or paper which does not curl down.

IMPORTANT |

Before loading envelopes, press all the way around the envelopes by hand on a level surface to fix any curls or bends. The Stack Bypass-C can hold 10 envelopes at a time. |

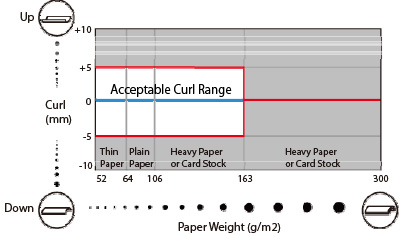

Acceptable curl range when the curl is parallel to the feed direction

If you feed paper from the main unit, POD Deck Lite-C, POD Deck Lite XL-A, or Multi-drawer Paper Deck-C

When the curl is parallel to the feed direction, there is a gap between the paper and the size change plates on the paper deck, and there is a risk of paper being fed at a slant. If you cannot avoid using curled paper, always ensure that the curl is within the range given in the graph below. However, Heavy Paper or Card Stock (164 to 300 g/m2) with this kind of curl cannot be used.

With Heavy Paper or Card Stock (164 to 300 g/m2), transport problems may occur regardless of the amount of curl. For LTR or smaller sizes, we recommend using paper with the grain parallel to the long edge (A). For sizes A3 or larger, we recommend using paper with the grain parallel to the short edge (B).

If you feed paper from the Stack Bypass-C

If you feed paper less than 105 g/m2 in weight, we recommend using paper which curls up or down less than 10 mm.

If you feed paper from 106 to 163 g/m2 in weight, we recommend using paper which curls up less than 10 mm or curls down less than 5 mm.

IMPORTANT |

If you feed paper from 164 to 300 g/m2 in weight, paper with no curl is not available. Before loading envelopes, press all the way around the envelopes by hand on a level surface to fix any curls or bends. The Stack Bypass-C can hold 10 envelopes at a time. |