Loading Paper

This section describes how to load paper.

Caution for Paper Curl

If paper jams or poor print quality occur, paper curl is often the cause. The paper stiffness, direction of curl, and amount of curl have a strong influence on how well the paper is transported through the machine. When loading paper, always adjust the curl amount to the appropriate level as described below.

Correcting Paper Curl

In order to prevent problems resulted from paper curl, it is necessary to uncurl paper appropriately.

The amount of curl that may cause problems depends on the paper type and thickness. Refer to the instructions below to correct the paper curl so that it is within the acceptable range, and then reload the paper.

Measuring Paper Curl

Place the paper on a horizontal surface. Place a ruler against the leading edge relative to the paper transport direction, and measure the curl at both ends. If it is a down curl, flip the paper over before measuring the curl.

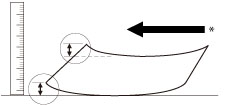

Measuring a perpendicular curl

* Transport Direction

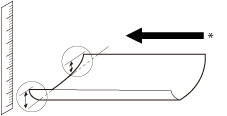

Measuring a parallel curl

* Transport Direction

Acceptable Curl Range

Acceptable curl range when the curl is perpendicular to the feed direction

We recommend using paper with a curl less than 5 mm. However, paper that is more than 164 g/m2 in weight and curls down is not recommended.

Acceptable curl range when the curl is parallel to the feed direction

We recommend using paper with a curl less than 5 mm. However, you cannot use curled heavy paper (164 g/m2 to 300 g/m2).