Finisher-AN1/Saddle Finisher-AN2/Puncher Unit-BS1/Puncher Unit-BT1

The Finisher-AN1 and Saddle Finisher-AN2 are equipped with the following finishing modes: Collate, Group, Offset, and Staple.

The Saddle Finisher-AN2 is also equipped with the Saddle Stitch mode.

If the Puncher Unit-BS1/Puncher Unit-BT1 is attached, the Hole Punch mode can also be used.

CAUTION CAUTION |

Do not place your fingers or hands on the finisher when the finisher is in use. Doing so may result in personal injury or damage to the finisher.  When removing paper from the tray of the finisher, do not place your hands on the output tray of the finisher. The tray may move upward and your hands may get caught. Do not place your hand in the part of the tray where stapling is performed (near the rollers) if a finisher is attached, as this may result in personal injury.  |

IMPORTANT |

Do not place anything other than output paper in the trays of the finisher, as doing so may damage the trays. Do not place anything under the trays of the finisher, as doing so may damage the trays.  If paper that is less than 17 lb bond (64 g/m2) is used for the cover page, the paper may be creased when saddle stitched. If paper that is less than 17 lb bond (64 g/m2) is used for the cover page when the Booklet Trimmer-D1 is attached, the paper may be trimmed with uneven edges. If the width of the paper you are using is small, the paper may be saddle stitched with uneven edges. In this case, check the width of the paper. If the width of the paper you are using is small, the paper may be stapled (Corner/Double) with uneven edges. In this case, check the width of the paper. If the width of the paper you are using is small when the Booklet Trimmer-D1 is used, the paper may be trimmed with uneven edges. In this case, check the width of the paper. If you create a saddle stitched booklet using coated paper for inserted sheets or the cover, the image printed on the page after the cover may stick to the back of the cover, or back of the inserted sheets, depending on the type of coated paper you are using. If you create a saddle stitched booklet or Staple (Corner/Double) mode using coated paper for inserted sheets or the cover, the copy sets may dirty the surface (toner streaks) of the cover depending on the type of coated paper you are using. If you create a saddle stitched booklet using coated paper for the cover, cracks may appear around the fold of the cover, depending on the type of coated paper you are using. If you use the Staple (Corner/Double) mode to staple multiple copy sets using coated paper for the cover, the staples of copy sets may dirty the surface of the cover of copy sets that have already been output, depending on the type of coated paper you are using. If paper with a weight of 120 to 129 lb cover (326 to 350 g/m2) is output to Tray A, the toner on the sheets of paper may stick to the sheets above. In this case, set Tray B as the output destination. Make sure not to allow thick, coated paper to stack up higher than 1 5/8" (40 mm) in Tray B. If paper with a weight of 120 to 129 lb cover (326 to 350 g/m2) is output to Tray B, paper jams and scratches in high density images may occur when high rigidity paper is used. |

Parts and Their Functions

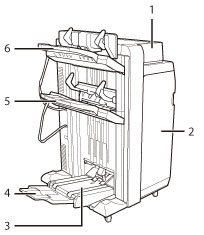

External View

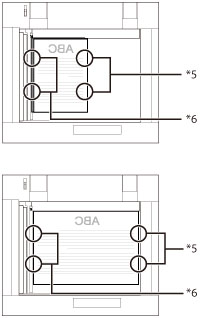

|  |

Saddle Finisher-AN2 | Finisher-AN1 |

1. | Top Cover Open this cover to remove jammed paper. (See "Clearing Paper Jams.") |

2. | Front Cover Open this cover to replace the staple cartridge, remove jammed paper, or clear a staple jam in the stapler unit and saddle stitcher unit. (See "Maintenance" and "Problem Solving.") |

3. | Booklet Tray (Saddle Finisher-AN2 Only) Prints that are saddle stitched are output to this tray. |

4. | Auxiliary Booklet Tray (Saddle Finisher-AN2 Only) Pull out the auxiliary tray if you are making a large size booklet. |

5. | Output Tray B Prints are output to this tray. You can set the Tray Designation mode to designate this tray for outputting prints when using certain functions. (See "Output Tray Designation.") |

6. | Output Tray A Prints are output to this tray. You can set the Tray Designation mode to designate this tray for outputting prints when using certain functions. (See "Output Tray Designation.") |

NOTE |

When attaching the Long Sheet Tray-A1 (optional), the extension output tray is attached to the head of Tray A. The Output Tray A/B aligns output paper by its two alignment guides. You can adjust the position of these guides. For more information, see "Paper Alignment on Finisher Tray A/B." |

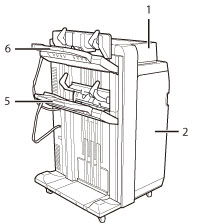

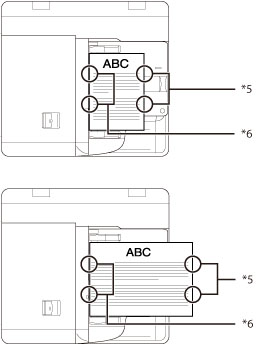

Internal View

1. | Punch Waste Tray (Puncher Unit-BS1/Puncher Unit-BT1) Pull out the punch waste tray to remove punch waste. (See "Removing Punch Waste (Puncher Unit-BS1/Puncher Unit-BT1).") |

2. | Staple Waste Tray Pull out the staple waste tray to discard the staple waste. (See "Removing Staple Waste (Finisher-AN1/Saddle Finisher-AN2).") |

Finishing Modes

The Finisher-AN1 and Saddle Finisher-AN2 are equipped with the following finishing modes:

Collate Mode

The prints are automatically collated into sets arranged in page order.

Group Mode

All prints of the same original page are grouped together into sets.

Offset Mode

The print output is shifted alternately to the front and back of the tray.

The paper is output in a vertical (portrait) or horizontal (landscape) orientation, depending on the orientation of your originals. For example, for LTRR originals, the paper is output in the horizontal direction. For LTR originals, the paper is output in the vertical direction.

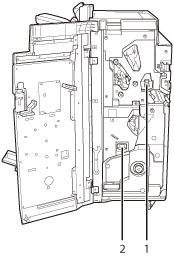

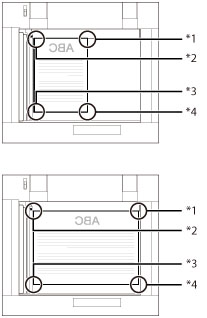

Staple Mode

The prints are automatically collated into sets arranged in page order and stapled. Prints are stapled in the following places:

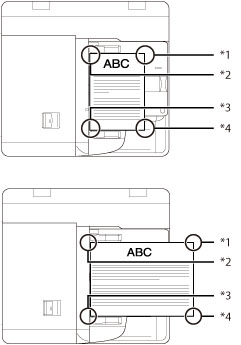

If an original is placed on the platen glass:

Corner Staple Area | Double Staple Area | |

|  |  |

*1 Upper Left *2 Upper Right *3 Lower Right *4 Lower Left | *5 Left Side *6 Right Side |

If originals are placed in the feeder:

Corner Staple Area | Double Staple Area | |

|  |  |

*1 Upper Right *2 Upper Left *3 Lower Left *4 Lower Right | *5 Right Side *6 Left Side |

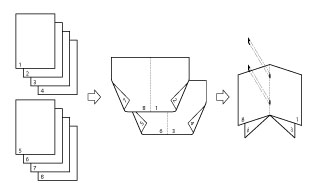

Saddle Stitch Mode

Prints are made into booklets, consisting of pages folded and stapled in the centre.

Hole Punch Mode

Two to four holes are punched in the printed sheets.

The hole punched areas are shown in the illustration below.

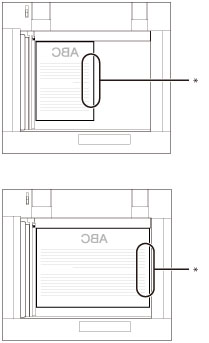

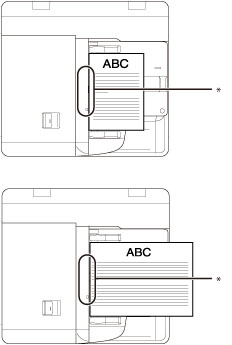

Platen Glass | Feeder |

|  |

* Hole Punched Area |

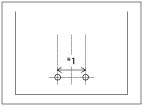

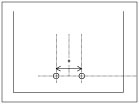

The distance between the punch holes is shown in the illustration below.

Puncher Unit-BS1

|  |

2 Holes | 3 Holes |

*1 2 3/4" (70 mm) *2 4 1/4" (108 mm) |

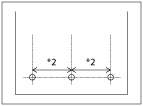

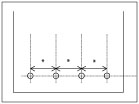

Puncher Unit-BT1

|  |

2 Holes | 4 Holes |

* 3 1/8" (80 mm) |

Saddle Fold Mode

The machine folds multiple sheets of paper into half its size.

IMPORTANT |

The following paper sizes can be stapled: Double staple: 11" x 17", LGL, LTR, LTRR, EXEC, or custom size (7 1/8" x 7 1/8" to 11 3/4" x 17" (182 mm x 182 mm to 297 mm x 432 mm)) Corner staple: 11" x 17", LGL, LTR, LTRR, EXEC, or custom size (8 1/4" x 7 1/8" to 11 3/4" x 17" (210 mm x 182 mm to 297 mm x 432 mm)) You cannot staple vellums, transparencies, clear film, translucent film, or labels. You also cannot staple the paper whose weight is 120 lb cover (326 g/m2) or more. The following paper sizes can be saddle stitched: 13" x 19", 12" x 18", 12 5/8" x 17 11/16", 11" x 17", LGL, LTRR, or custom size (8 1/4" x 11" to 13" x 19 1/4" (210 mm x 279.4 mm to 330.2 mm x 487.7 mm)) You cannot saddle stitch vellums, transparencies, clear film, translucent film, pre-punched paper, tab paper, or labels. You also cannot saddle stitch the paper whose weight is 111 lb cover (301 g/m2) or more. The following paper sizes can be hole punched: When the Puncher Unit-BS1 is attached. Two holes: 11" x 17", LGL, LTR, LTRR, EXEC, custom size (7 1/8" x 7 1/8" to 11 3/4" x 17" (182 mm x 182 mm to 297 mm x 432 mm)), custom size (11 3/4" x 7 1/8" to 12" x 18" (297.1 mm x 182 mm to 304.8 mm x 457.2 mm)) Three holes: 11" x 17", LTR, EXEC, custom size (8 1/4" x 7 1/8" to 11 3/4" x 17" (210 mm x 182 mm to 297 mm x 432 mm)), custom size (11 3/4" x 7 1/8" to 12" x 18" (297.1 mm x 182 mm to 304.8 mm x 457.2 mm)) When the Puncher Unit-BT1 is attached. Two holes: 11" x 17", LGL, LTR, LTRR, EXEC, custom size (7 1/8" x 7 1/8" to 11 3/4" x 17" (182 mm x 182 mm to 297 mm x 432 mm)), custom size (11 3/4" x 7 1/8" to 12" x 18" (297.1 mm x 182 mm to 304.8 mm x 457.2 mm)) Four holes: 11" x 17", LTR, EXEC, custom size (10 1/8" x 7 1/8" to 11 3/4" x 17" (257 mm x 182 mm to 297 mm x 432 mm)), custom size (11 3/4" x 7 1/8" to 12" x 18" (297.1 mm x 182 mm to 304.8 mm x 457.2 mm)) You cannot punch holes in heavy 6 to 8, 1-sided coated 7 to 9, 2-sided coated 7 to 9, matte coated 7 to 9, transparencies, clear film, translucent film, textured 7, vellums, labels, and pre-punched paper. You also cannot punch holes in paper whose weight is 113 lb cover (301 g/m2) or more. The following paper sizes can be saddle folded: 13" x 19", 12" x 18", 12 5/8" x 17 11/16", 11" x 17", LGL, LTRR, or custom size (8 1/4" x 11" to 13" x 19 1/4" (210 mm x 279.4 mm to 330.2 mm x 487.7 mm)) You cannot saddle fold vellums, transparencies, clear film, translucent film, pre-punched paper, tab paper, or labels. You cannot fold paper whose weight is 111 lb cover (301 g/m2) or more. In the following cases, output paper may not be aligned, or may fall down from the tray: When using thin paper (due to the temperature, humidity, characteristics of the paper type, or paper curling) When the hole punch mode is set When using custom paper sizes, and both the Hole Punch mode and the Offset mode are set, the edge of paper may become curled or creased. In this case, set the Offset mode to 'Off'. |

NOTE | ||||||||

For instructions on maintenance for the finisher, such as replacing staples, see "Maintenance." For information on clearing paper or staple jams, see "Problem Solving." If the Finishing mode is set, the output trays move downward as the stack of paper that is output increases in quantity and thickness. Once an output tray has reached its stacking limit, subsequent prints are automatically delivered to the next available tray. If all of the available trays have reached their stacking limits, printing stops. Remove all of the output paper from the trays. The trays move upward, and printing resumes. You cannot output stapled paper to the Tray A. If you press [Offset]*1 when either the Collate or Group mode is set, each set of prints is shifted the following amount before it is delivered to the output tray. *1 Paper with a width of 12" (304.9 mm) or more or a length of 19 1/4" (487.8 mm) or more cannot be shifted.

If the Staple mode is set, the output tray moves downward as the stack of paper that is output increases in quantity and thickness. Once an output tray has reached its stacking limit, or after 200 sets of prints or the predefined height has been output, printing and stapling stop temporarily. When all of the stapled prints from the output tray are removed, printing and stapling resume. When you are using the Staple mode, do not remove the stack of paper from the output tray during the job. Remove the stack of paper when the job has been completed. The Staple-N1 is standardly equipped on the Finisher-AN1. The Staple-N1 and Staple-P1 are standardly equipped on the Saddle Finisher-AN2. If you want to use the Staple mode with more than 50 sheets (20 lb bond (80 g/m2)) of 11" x 17", LGL, or LTRR paper, or 100 sheets (20 lb bond (80 g/m2)) of LTR or EXEC paper, the copies/prints are only offset but not stapled. In addition, when selecting coated or heavy paper, you may not be able to use the Staple mode even if the number of sheets, including sheet insertions or job separators, is below the set limit of a finisher. The maximum number of bindable sheets may not be possible, depending on the paper type. In this case, change the paper type, or reduce the number of sheets to bind. If the machine stops while stapling and the message <Load staples into the stapler unit.> appears, almost all of the staples have been used, and the staple case must be replaced. To proceed, replace the staple case. (See "Maintenance.") The Saddle Stitch mode is available only if the Saddle Finisher-AN2 is attached. The maximum number of sheets that can be saddle stitched differs depending on the paper weight and type. For example, when using plain paper (20 lb bond (80 g/m2)), 25 sheets of paper (100 pages) can be saddle stitched at once. The accuracy of folds created in the Saddle Stitch mode may vary depending on the paper type and the number of sheets. For information on the maximum number of sheets that can be Z-folded and stapled when the Paper Folding Unit-J1 is attached, see "Staple Mode with the Z-fold Mode." The Hole Punch mode is available only if the Puncher Unit-BS1/Puncher Unit-BT1 is attached. The Saddle Fold mode is available only if the Saddle Finisher-AN2 is attached. The paper is saddle folded with a maximum of 5 sheets (20 lb bond (80 g/m2)), and then output. |

Paper Sizes that can be Output

The paper sizes that can be output from the output trays of the Finisher-AN1/Saddle Finisher-AN2 are indicated below. However, some paper sizes may not be output depending on the set functions.

: Available

: Available-: Unavailable

Paper Size | Tray A | Tray B | Booklet Tray | |

13" x 19" |  |  |  | |

12" x 18" |  |  |  | |

12 5/8" x 17 11/16" |  |  |  | |

11" x 17" |  |  |  | |

LGL |  |  |  | |

LTR |  |  | - | |

LTRR |  |  |  | |

STMTR |  | - | - | |

EXEC |  |  | - | |

Custom Size | 5 1/2" x 7 1/8" to 13" x 19 1/4" (139.7 mm x 182 mm to 330.2 mm x 487.7 mm) |  |  *1 *1 |  *2 *2 |

Custom Size (Long Sheet) | 8 1/4" x 19 1/4" to 13" x 30" (210 mm x 487.8 mm to 330.2 mm x 762 mm) |  *3 *3 | - | - |

*1 Custom paper sizes can only be output if they are between 7 1/8" x 7 1/8" to 13" x 19 1/4" (182 mm x 182 mm to 330.2 mm x 487.7 mm).

*2 Custom paper sizes can only be output if they are between 8 1/4" x 11" to 13" x 19 1/4" (210 mm x 279.4 mm to 330.2 mm x 487.7 mm).

*3 Post processes such as stapling and punching holes cannot be done.

NOTE |

The Booklet Tray can only be used when the Saddle Finisher-AN2 is attached. You cannot output paper whose width is less than 7 1/8" (182 mm) to the Output Tray B. |