Adjusting Gradation

The maximum density and balance of the CMYK toner that is originally output will vary due to fluctuations in the operating environment (temperature and humidity) and continuous output. The automatic gradation adjustment is a function that always maintains an optimal density balance. There are two types of adjustments: Full Adjustment and Quick Adjustment.

|

Make sure to perform this function in the stable room environment (i.e. temperature and humidity). The color may become unstable due to the rapid changes in room environment, especially soon after staring up an air conditioner during summer or winter season. It is recommended that you select <Full Adjust> when performing an automatic gradation adjustment. Select <Quick Adjust> for a quick, but less complete adjustment between regular full adjustment recalibrations. This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type. Make sure that you place the test pages properly. Accurate recalibrations of the gradation, density, and color settings of the machine cannot be made if the test pages are not scanned correctly. |

Full Adjustment

Correct the gradation of an image accurately and optimize reproducibility during printing. Optimized information will be retained until the next accurate correction.

Adjusting using the feeder (optional)

In this procedure, you need to scan the printed test pages twice to correct gradation. This consumes 3 to 11 sheets of paper. The number of sheets consumed depends on the number of sheets set in <Number of Sheets to Output for Test Page>.

|

You can use the following paper. Make sure that the following paper is loaded in the paper source before operating. Size: A3, 11" x 17" Basis Weight/Finish/Whiteness: Canon SAT023 Top Colour Zero FSC (100 g/m²)* or the paper type registered/selected as paper to adjust * The name of the paper is subject to change without notice. For more information, contact your local authorized Canon dealer. |

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>. When the optional In-line Spectrophotometer-A is attached

When the optional In-line Spectrophotometer-A is attached

1 | Press <Select Method>. |

2 | Press <Use Scanner>  <Feeder> <Feeder>  <OK>. <OK>. |

When the optional In-line Spectrophotometer-A is not attached

When the optional In-line Spectrophotometer-A is not attached

1 | Select <Use Feeder When Performing Full Adjust>. |

2

Press <Full Adjust>.

3

Select the paper source that the paper for the test print is loaded, and press <OK>.

4

Press <Start Printing>.

The first test page is output.

5

Place the output test page in the feeder, and press <Start Scanning>.

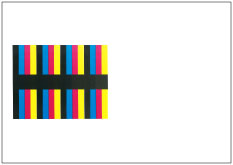

Place the first test page in the feeder with the black bar along the right edge.

6

Remove the first test page from the feeder, and press <Start Printing>.

The second test page is output.

7

Place the second output test page in the feeder, and press <Start Scanning>.

Place the second test page face down in the feeder, with the black bar innermost.

8

Remove the second test page from the feeder.

Adjusting using the platen glass (optional)

In this procedure, you need to scan the printed test pages three times to correct gradation. This consumes 3 to 11 sheets of paper. The number of sheets consumed depends on the number of sheets set in <Number of Sheets to Output for Test Page>.

|

You can use the following paper. Make sure that the following paper is loaded in the paper source before operating. Size: A3, 11" x 17" Basis Weight/Finish/Whiteness: Canon SAT023 Top Colour Zero FSC (100 g/m²)* or the paper type registered/selected as paper to adjust * The name of the paper is subject to change without notice. For more information, contact your local authorized Canon dealer. |

1

Press

<Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

<Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.  When the optional In-line Spectrophotometer-A is attached

When the optional In-line Spectrophotometer-A is attached

1 | Press <Select Method>. |

2 | Press <Use Scanner>  <Platen Glass> <Platen Glass>  <OK>. <OK>. |

When the optional In-line Spectrophotometer-A is not attached

When the optional In-line Spectrophotometer-A is not attached

1 | Deselect <Use Feeder When Performing Full Adjust>. |

2

Press <Full Adjust>.

3

Select the paper source in which the paper type to use for test page is set, and press <OK>.

4

Press <Start Printing>.

First test page is output.

5

Place the first test page on the platen glass, and press <Start Scanning>.

Place the first test page face down on the platen glass, with the black bar along the left edge of the platen glass.

6

Remove the first test page from the platen glass, and press <Start Printing>.

Second test page is output.

7

Place the second test page on the platen glass, and press <Start Scanning>.

Place the second test page face down on the platen glass, with the black bar along the top back edge of the platen glass.

8

Remove the second test page from the platen glass, and press <Start Printing>.

Third test page is output.

9

Place the third test page on the platen glass, and press <Start Scanning>.

Place the third test page face down on the platen glass, with the black bar along the top back edge of the platen glass.

10

Remove the third test page from the platen glass, and press <Start Printing>.

Fourth test page is output.

11

Place the fourth test page on the platen glass, and press <Start Scanning>.

Place the fourth test page face down on the platen glass, with the black bar along the top back edge of the platen glass.

12

Remove the fourth test page from the platen glass.

Adjusting using the In-line Spectrophotometer-A (optional)

The machine repeatedly scans the test pages automatically to correct gradation. This consumes 10 to 18 sheets of paper. The number of sheets consumed depends on the number of sheets set in <Number of Sheets to Output for Test Page>.

|

You can use the following paper. Make sure that the following paper is loaded in the paper source before operating. Size: A3, 11" x 17", 320 mm x 450 mm(SRA3), 12" x 18" or 13" x 19" Basis Weight/Finish/Whiteness: Canon SAT023 Top Colour Zero FSC (100 g/m²)* or the paper type registered/selected as paper to adjust * The name of the paper is subject to change without notice. For more information, contact your local authorized Canon dealer. |

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>. When the optional Duplex Color Image Reader Unit-P is attached

When the optional Duplex Color Image Reader Unit-P is attached

1 | Press <Select Method>. |

2 | Press <Do Not Use Scanner>  <OK>. <OK>. |

2

Press <Full Adjust>.

3

Select the paper source that the paper for the test print is loaded, and press <OK>.

4

Press <Start Printing>.

The test page is printed, and then the adjustment will be performed automatically.

Quick Adjustment

This adjustment maintains the optimized status that was acquired by <Full Adjust>. If the result of this adjustment is not satisfactory, perform <Full Adjust>.

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.2

Select the paper to adjust, and press <Quick Adjust>.

If you selected <Normal> in <Adjustment Level>, you do not need to select the paper. Correction is applied to all paper types.

3

Press <Start>.

Registering Paper for Calibration

If you perform automatic gradation adjustment for a custom paper type, registering a custom paper type for calibration is required beforehand.

In this procedure, you need to scan the printed test pages 2 times, 1 time for base paper and 1 time for a custom paper type. The number of sheets required for the registration is 2 sheets of paper.

| ||||

Make sure to register paper to adjust in the stable room environment (i.e. temperature and humidity). If the rapid changes in room environment occur after the registration of paper to adjust, accurate recalibrations of the gradation, density, and color settings of the machine cannot be made for paper already registered to adjust. In this case, register again that paper to adjust. Make sure to register paper whose finish and whiteness are equivalent to the Canon SAT023 Top Colour Zero FSC (100 g/m²)as paper to adjust. Accurate recalibrations of the gradation, density, and color settings of the machine may not be made if you register and use paper other than that condition as paper to adjust. To perform the procedure described in this section, you must log in to the machine as an administrator. Logging in as an Administrator Confirm that both paper to use as a basis and a custom paper type to register to adjust, described in the following table, are set in paper sources correctly before starting this procedure.

* The name of the paper is subject to change without notice. For more information, contact your local authorized Canon dealer. |

|

<Custom Type> registered in <Paper Information> of <Paper to Adjust 1>, <Paper to Adjust 2>, and <Paper to Adjust 3> becomes unable to be changed or deleted. If you want to delete or change <Custom Type>, first register another <Custom Type> as the paper to adjust. Paper Type Management Settings |

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.2

Press <Register Paper to Adjust>.

3

Select the destination for registering new paper to adjust, and press <Next>.

|

You can register up to three type of paper to adjust and you can overwrite them. When overwriting, you cannot restore the paper settings previously registered. |

4

Select the type for the paper to use as a basis, and press <Next>.

5

Select the paper source contains the type of paper to use as a basis, and press <Next>.

|

This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type. |

6

Press <Start Printing>.

First test page is output.

7

Place the first test page on the platen glass, and press <Start Scanning>.

Place the first test page face down on the platen glass, with the black bar along the top back edge of the platen glass.

8

Remove the first test page from the platen glass.

9

Select the paper source that contains the custom paper type to adjust, and press <Next>.

|

This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type. |

10

Press <Start Printing>.

Second test page is output.

11

Place the second test page on the platen glass, and press <Start Scanning>.

Place the second test page face down on the platen glass, with the black bar along the top back edge of the platen glass.

12

Remove the second test page from the platen glass.

Selecting Paper for Calibration

You can select the type of paper for calibration.

|

To perform the procedure described in this section, you must log in to the machine as an administrator. Logging in as an Administrator |

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.2

Press <Select Paper to Adjust>  select the type of paper to adjust press

select the type of paper to adjust press  <OK>.

<OK>.

select the type of paper to adjust press

select the type of paper to adjust press  <OK>.

<OK>. |

This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type. To perform the auto gradation adjustment to some custom paper type, select that custom paper type, which is registered in advance, for paper to adjust. |

Initializing Standard Values for Calibration

If you perform automatic gradation adjustment but cannot adjust gradation, density, or color correctly, or scanned error message appears for the test page, set <Initialize When Using Full Adjust> to <On>, and then perform <Full Adjust>.

1

Press  (Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.

(Settings/Registration)

(Settings/Registration)  <Adjustment/Maintenance>

<Adjustment/Maintenance>  <Adjust Image Quality>

<Adjust Image Quality>  <Auto Adjust Gradation>.

<Auto Adjust Gradation>.2

Press <Initialize When Using Full Adjust>  <On>

<On>  <OK>.

<OK>.

<On>

<On>  <OK>.

<OK>.3

Perform Full Adjust by following steps 2 to 4 in  Full Adjustment.

Full Adjustment.

Full Adjustment.

Full Adjustment.